Copper Heatsinks

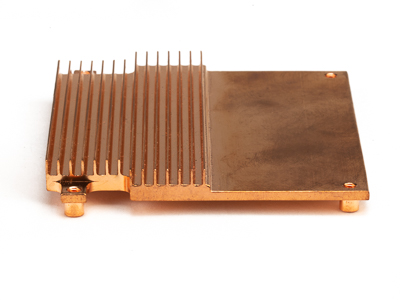

This said, though, it is worth mentioning that one very advantageous use of copper is found through the process of Skived Fin Technology. In this production method, a single block of copper is carved out of and ultimately a unified heatsink is created. The benefits to skiving copper are experienced through the increased efficiency created by having the heat source base attachment integrally connected to the cooling fins. In addition, copper's increased rate of thermal conveyance makes a skiving solution an extremely desirable heatsink design.

Another very common alternative to all-copper heatsinks is the joining together of copper and aluminum in a single heatsink. This can be achieved by affixing multiple aluminum fins to a copper heatsink base. With this design for partially copper heatsinks, the designer will be rewarded by a high initial thermal transmission from the heat source which is then quickly conveyed to the aluminum fins. Such a system for copper heatsinks is ideal because it combines the benefits of both materials; while high conductivity is needed at the base of the heatsink, the light weight, extrusion capability and affordability of aluminum can be exploited by choosing this metal for use in the heatsink fins.

For Your Next Project, Contact CoolianceToday!

High reliability thermal solutions & precision metal products.