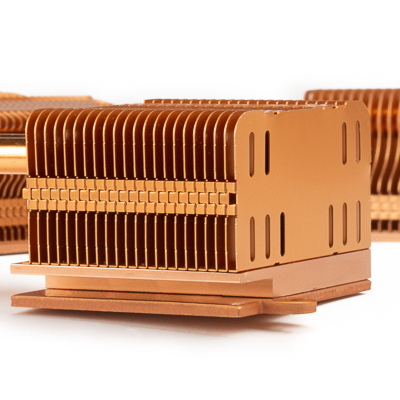

Stamped Pin Heatsinks

The major improvements that stamped fin heat sinks have been able to achieve over conventional heat sink designs include a long list of features ranging from extreme fin thinness to high density and from limited restrictions on fin height to strong levels of compatibility with external attachments when they are needed. The thinness that fins can achieve with stamped fin heatsink technology is dramatically more advanced than conventional extrusion heatsinks. While special cutting technique can bring extrusions down to just under a fifth of an inch, stamping is able to double the thinness. This is extremely useful for attaining the high surface area needed to effectively disperse thermal energy from the heatsink.

Stamped fin heat sinks provide the much needed solution to a variety of application requirements. For one, the combination of copper, aluminum - and sometimes nickel plating - when designing stamped fin heatsinks is exceptionally responsive to the cooling needs of increased performance circuitry, such as overclocked computers. Other uses for stamped fin heat sinks include applications with forced convection currents, chips with high power - usually over a hundred watts - and small, hard-to-fit space requirements.

For Your Next Project, Contact CoolianceToday!

High reliability thermal solutions & precision metal products.