Heatsink Design

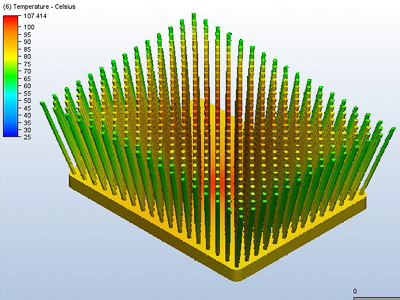

Yet raising the surface level by adding smaller fins comes at the expense of the strong thermal transfer power of thicker fins. The best heat sink design finds a balance between thick and thin fins. With high thermal conductivity, thick fins are advantageous to bringing heat over to the important cooling fins.

Making sure that cooling fins are well ventilated is another crucial aspect of an effective heat sink design. Again, a balance must be found between high surface area and good airflow. With complex systems of fins set close to one another, it can be harder for air to get through to all of the cooling fins. Sometimes fans can be used to push air through the many layers of thins, as long as the heat sink is designed for this.

The best way to design heat sink mounting is with springs and screws in mind. As the heat sink is a conductor of thermal energy, it must be firmly affixed to its source of heat. Another way to attach heat sinks is with clips specially designed to apply strong pressure to the heat source.

Maximizing thermal energy transfer is dependent upon the attaining the perfect level of flatness of the heat sink at its point of contact with the heat source. This flatness greatly decreases thermal resistance and is a feature found in the best heat sink designs.

See how Cooliance's custom heatsink design services can help you.

For Your Next Project, Contact CoolianceToday!

High reliability thermal solutions & precision metal products.