Not all LED Heatsinks are made equal!

Cooliance provide high-performance pin fin led heatsinks pre-drilled for the Bender+Wirth 439 series LED holder which is compatible with the following COB LEDs:

- CREE CXA 2520, CXA2530, CXA 2540, CXA 2590, CXB 2520, CXB 2530, CXB 2540, CXB 2530

Product Customization Services

In addition to our range of standard products detailed in the table below, we can customize our product offering for your unique application. For more information, please contact our technical support team.

If you need something different from what is detailed below, a different product or customization, please contact our technical support team who will assist you in selecting the correct heatsink for your project.

Standard Coolstrate Heatsink

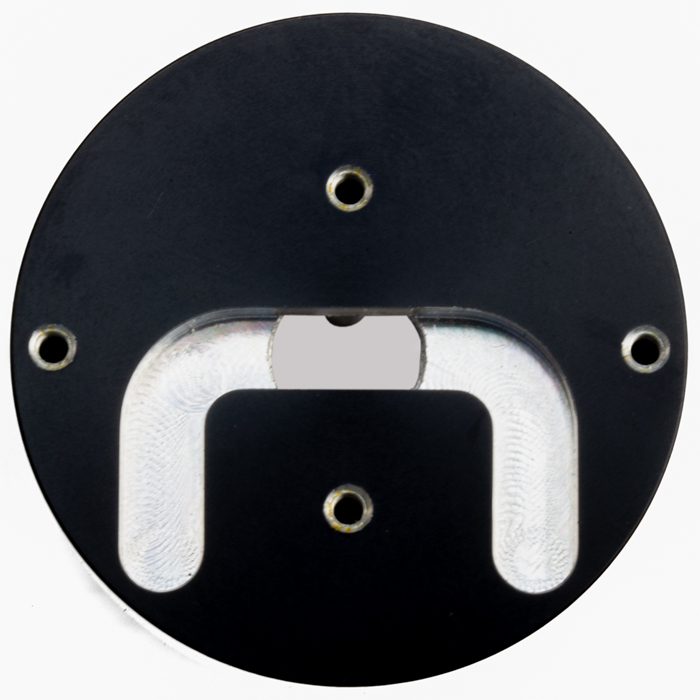

Base Modified for Cable Management

Cable harness

Typical, LED Assembly

Coolstrate® is silent and reliable, well-exceeding the life of your light engine

- Inaudible at one meter

- No issues of resonance – multiple units mounted together are as silent as a single unit

- Long-life motor design keeps our units silent for years

- Coolstrate® fans are designed to operate trouble-free for over 60,000 hours

- Double-bearing industrial fans, produced in the hundreds of thousands and with proven reliability records

- Double-bearing fans do not suffer from sudden failure, unlike sleeve-bearing based designs

- Double-bearing fans are indifferent to orientation, unlike sleeve-bearing based designs

- Heavy-duty, high-density pin fin heat sinks are designed to eliminate internal dust build-up – our field tests prove it

- Robust mounting clip protects the fan from shock and virtually eliminates accidental damage

- No separate driver is required – you have the full range of choice for the driver that best meets your lighting requirements

- Easy application testing – with a full range of standard sizes and multiple fan speeds, we make it easy for you to address the trade-offs between size constraints and power

- Coolstrate®'s 10mm, perfectly flat base gives you maximum security for reliable mounting of your Bridgelux array, as well as full freedom in hole placement for mounting points, wire guides and reflector attachments

Modified With Wireways & Mounting Holes

Need Description

Need Description

Modified with Wireways, IP rated When Fulled With Silicon

Cold Forged Construction For Thermal Efficiency

Standard Passive LED Heatsinks are available in the following sizes:

- Diameters of 20 mm to 160 mm are offered within the standard product family. Consult factory for other sizes.

- Pin heights of up to 100mm are available

Standard or modified standard solutions - We can provide a solution from our standard product line and model it to ensure that it will provide adequate cooling for your application..

Our precision forge process provides unique advantages for LED cooling:

- Forging can produce round and other non-linear shapes that are preferred for LED applications.

- The forge process uses high pressure to form the material and provides control over the grain structure to provide superior thermal performance.

- LED’s are generally convection cooled and our forged pin fin arrays provide the best possible thermal performance in ambient environments.

- Heat sinks can be forged in either aluminum or copper.

Custom design services - Our thermal engineers can also work with you to design and model a custom solution optimized to meet the needs of your application.

For Your Next Project, Contact CoolianceToday!

High reliability thermal solutions & precision metal products.