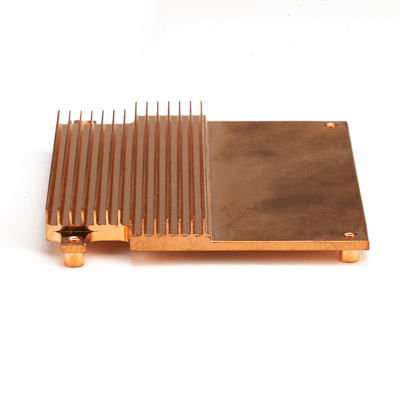

Custom Heatsinks

In order to determine the customization requirements for a particular component's heatsink needs, it is important to understand that the spatial and thermal restrictions that most frequently compel manufacturers to implement custom heatsinks are either based on size constraints, special cooling needs or mounting concerns. In addition, many find that they can derive better performance from their components by specially outfitting a heatsink solution that pulls more heat and thereby allows for more thermal activity overall.

Although the general procedure for customization may vary slightly from company to company, the general method of having a job done is begun by sending in the circuit board that needs to be set up with a custom heat sink. Once having obtained this, the heatsink manufacturer will use specialized software to run a simulation of the thermal flow requirements of the component. After this is done, a plan will be drawn up for the optimized heatsink solution and, upon the approval of the client the prototype will be created so that mass production can begin as quickly as possible. Thanks to some companies' rapid prototyping capacities, the production time for customized heatsinks has been cut down dramatically.

In addition to heatsink design, there is often a need for additional accessories to custom heatsink designs that varies widely depending upon the type of heatsink being used. Frequently there is a need to find the best method of affixing a heatsink to the component that it serves, and for this there is a varied list of options. BGA heatsinks, for example, may be attached using Smartclip technology while converters from DC to DC use more advanced kits for mounting. Alternatively, CPU heatsinks might require a type of socket clip for mounting.

For Your Next Project, Contact CoolianceToday!

High reliability thermal solutions & precision metal products.